Importants of Fresh concrete need to vibrated

Here we disscuss about importants of Fresh concrete need to vibrated given below in detailed.Freshly placed, uncompacted concrete is usually full of entrapped air bubbles.Concrete will only achieve a high compressive strength and density with minimum air content through the use of mechanical means, i. e. the introduction of high frequency (fast, repetitive) vibrations.

Only in this way can concrete meet today’s requirements in terms of strength and density. The high frequency vibrations generated by the vibrator are transmitted to the components of the fresh concrete.

• Frictional forces between individual particles are substantially reduced.

• A flow process is created.

• Air bubbles, excess water and paste entrapped through capillary action and surface tensions are released and escape to the surface.

Advantages of concrete vibration

• Greater density and homogeneity

• Greater compressive strength

• Greater durability (e. g. de-icing salt)

• Better bond with rebar, particularly in densely reinforced sections

• Better bond between the individually “wet” on “wet” placed layers

• Improved quality exposed (fair-faced) surfaces

• Makes possible use of drier mixtures,thus requiring less cement.

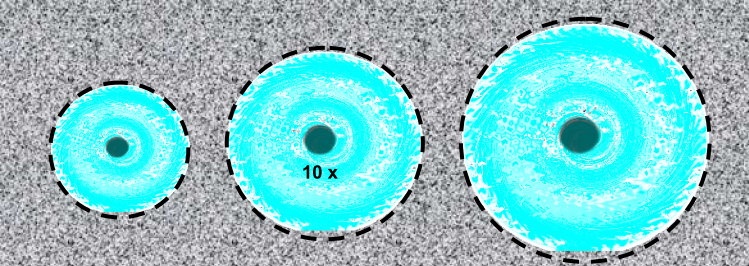

Know your effective compaction diameter:

For practical purposes and as rule of thumb consider the operating diameter to be approx. 10 times the vibrator head housing diameter.

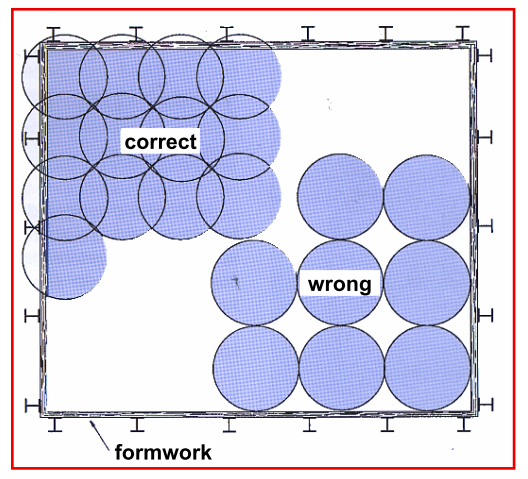

Maintain correct spacing when compacting large surfaces

Correct spacing when vibrating fresh concrete in walls

Internal vibrators with Ø 30 (1.2”), 38 (1 ½”) and 45 mm (1.8”) should not be used due to poor or non-existing overlapping of the effective compaction Ø. This will lead to a faulty or uneconomical vibration process.

For greater effective compaction Ø and for more convenient, economical compaction (less insertions, less time) preferably use only

• vibrators with diameters 57 or 65 mm, provided the rebar allows it.

• The concrete will be compacted faultlessly thanks to the overlapping.

Layer depths when vibrating fresh concrete

Practical experience has shown that evenly and horizontally spread layers of provide the best results in concrete compaction.approx. 50 cm (20”) thickness.

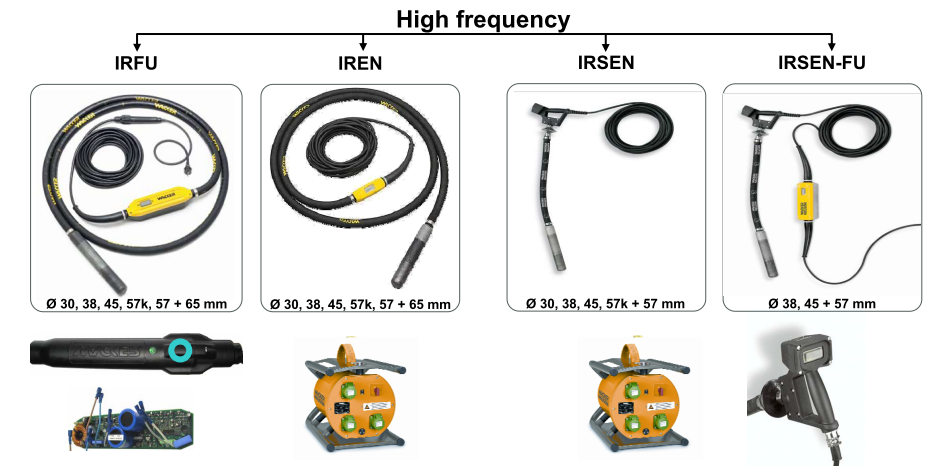

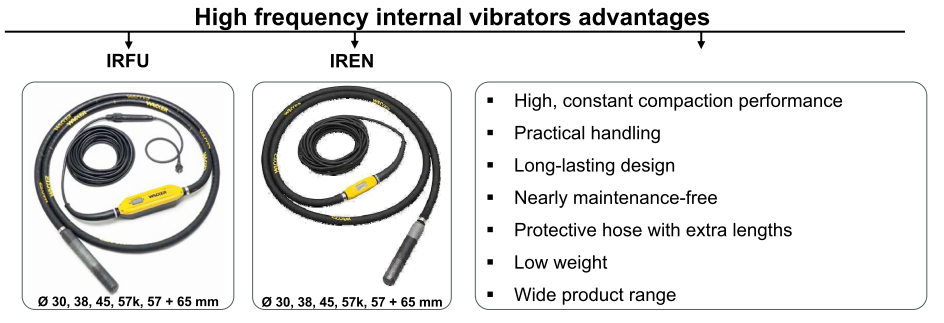

Concrete vibrating equipment: Internal vibrators