Use and Advantages Precast Concrete

Precautions of Precast

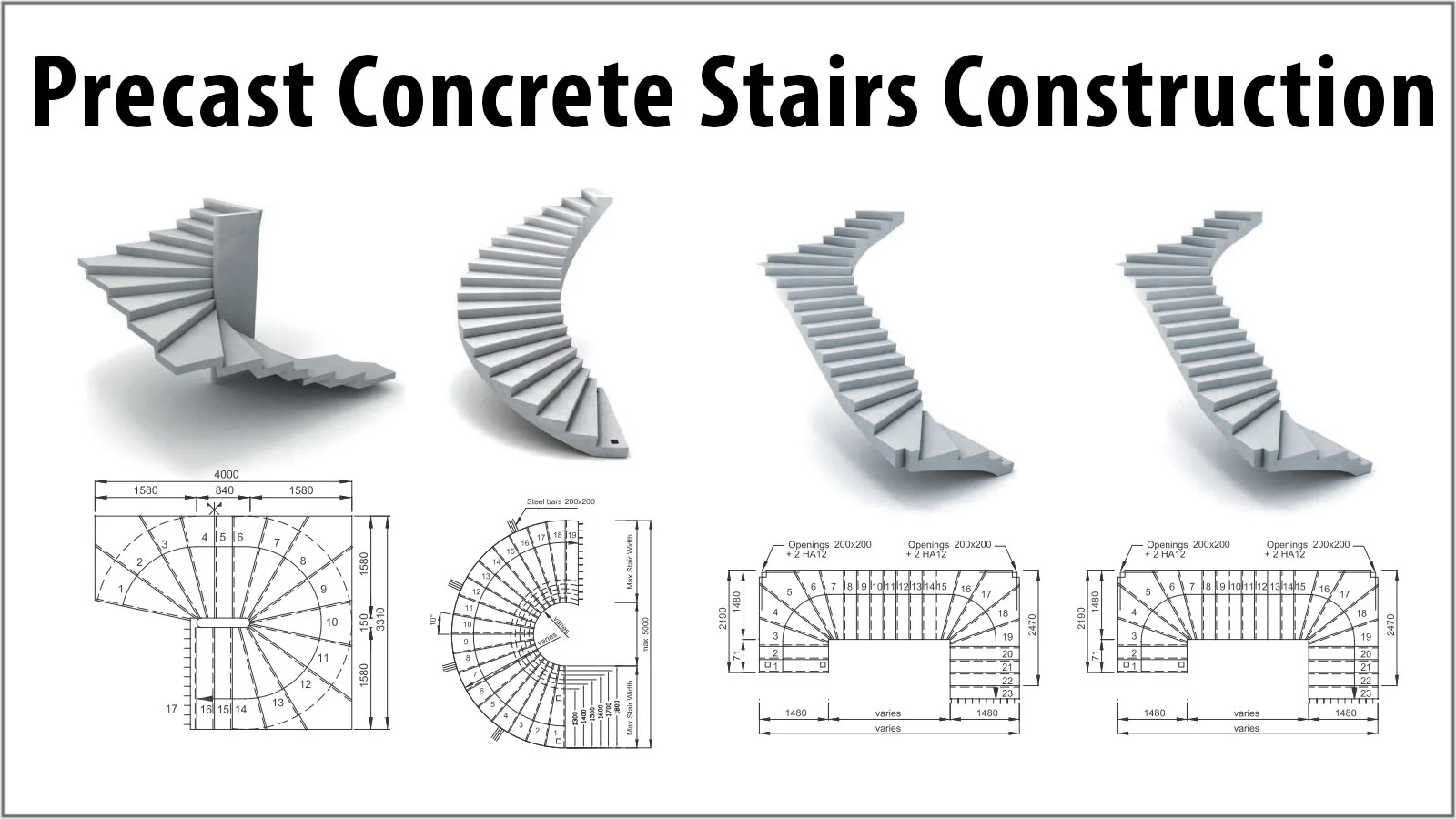

Precast concrete is simply concrete that is cast somewhere other than where it will be used. Most precast products are cast in a factory using a wetcast method, but others are cast on site-such as tilt-up panels. There are lots of reasons-mostly advantages-why one would precast, and we’ll get into those, but the biggest negative of precasting is that the resultant concrete item must be moved. Concrete is heavy-typically about 150 pounds per cubic foot-so concrete elements don’t have to be very big before moving them becomes unrealistic.Some decorative contractors, such as those that precast concrete countertops, stretch the boundaries on what’s too big or heavy to move, developing special rigs to transport massive pieces of their concrete work. Other times,it’s just simpler to cast the concrete in place as the precast advantages are outweighed by convenience, such as with concrete slabs and floors.

Precasting offers contractors an opportunity to make more money-to increase the scope of the types of concrete work they can offer their customers. To begin precasting, you will need a shop large enough to accommodate the size of the pieces you intend to precast (or a yard if you intend to precast outside), material storage areas or bins,molds, a mixer sized for the precast products you are making, a way to consolidate the concrete in the molds, and a material handling system.

Why use precast concrete?

There are many benefits associated with the use of precast concrete components.Of course these require proper design, use of the correct materials and manufacturing processes with skilled and knowledgeable personnel. Benefits available include:-

Quality , Durability, Dimensional accuracy, Tight tolerances, Speed of construction,Reduction of on site labour, Reduction of on site activity, noise, and distur-bance, Reduction of on site waste, Low life cycle cost, Minimal maintenance Non , Combustible, Fire rated, Not subject to rot, Acoustic insulation, Thermal inertia reduces lifetime energy costs, Sandwich panels available for insulation,. Large spans available from prestressing.These impact on all parties providing benefits for the architect, engineer, builder, developer, and owner.The benefits are many, including financial gains from shorter construction times and earlier occupation.

Advantages of Precast Concrete

The concrete of superior quality is produced as it is possible to have better technical control on the production of concrete in factory. It is not necessary to provide joints in the precast construction.The labour required in the manufacturing process of the precast units can easily be trained.The moulds employed for preparing the precast units are of steel with exact dimension in all directions. These moulds are more durable and they can be used several times.

The precast articles may be given the desired shape and finish with accuracy.The precast structures can be dismantled, when required and they can then be suitably used else where.

The transport and storage of various components of concrete for cast in situ work are eliminated when precast members are adopted

Read More

Advantages of Precast Concrete and Disadvantages its Uses

Prestressed Concrete in Construction