Functional classification of Site Work Inspection

Functional classification of Site Work Inspection

Inspection activities and organizations are Site Work Inspection mainly concerned with the following four functions:

Acceptance inspection A series of formalized activities and procedures that provide the owner of the structure being built, with an acceptable degree of assurance that the contractor has satisfied his or her obligations to construct in accordance with the contract documents. The evaluation of tests performed and of the observation of procedures and practices used in the construction should permit the determination of conformance to prescribed acceptance standards.

Quality-control inspection contractor Quality control inspection by the contractor is a series of formalized activities and procedures that are part of the contractor’s operation, providing in-process evaluation of the quality of construction. This helps to ensure the contractor that the finished construction will meet all requirements of the project plans, drawings, and specifications, and will be accepted by the owner’s representative.

Collection 𝐎𝐧𝐥𝐢𝐧𝐞 𝐂𝐢𝐯𝐢𝐥 𝐅𝐢𝐥𝐞𝐬 Click Here

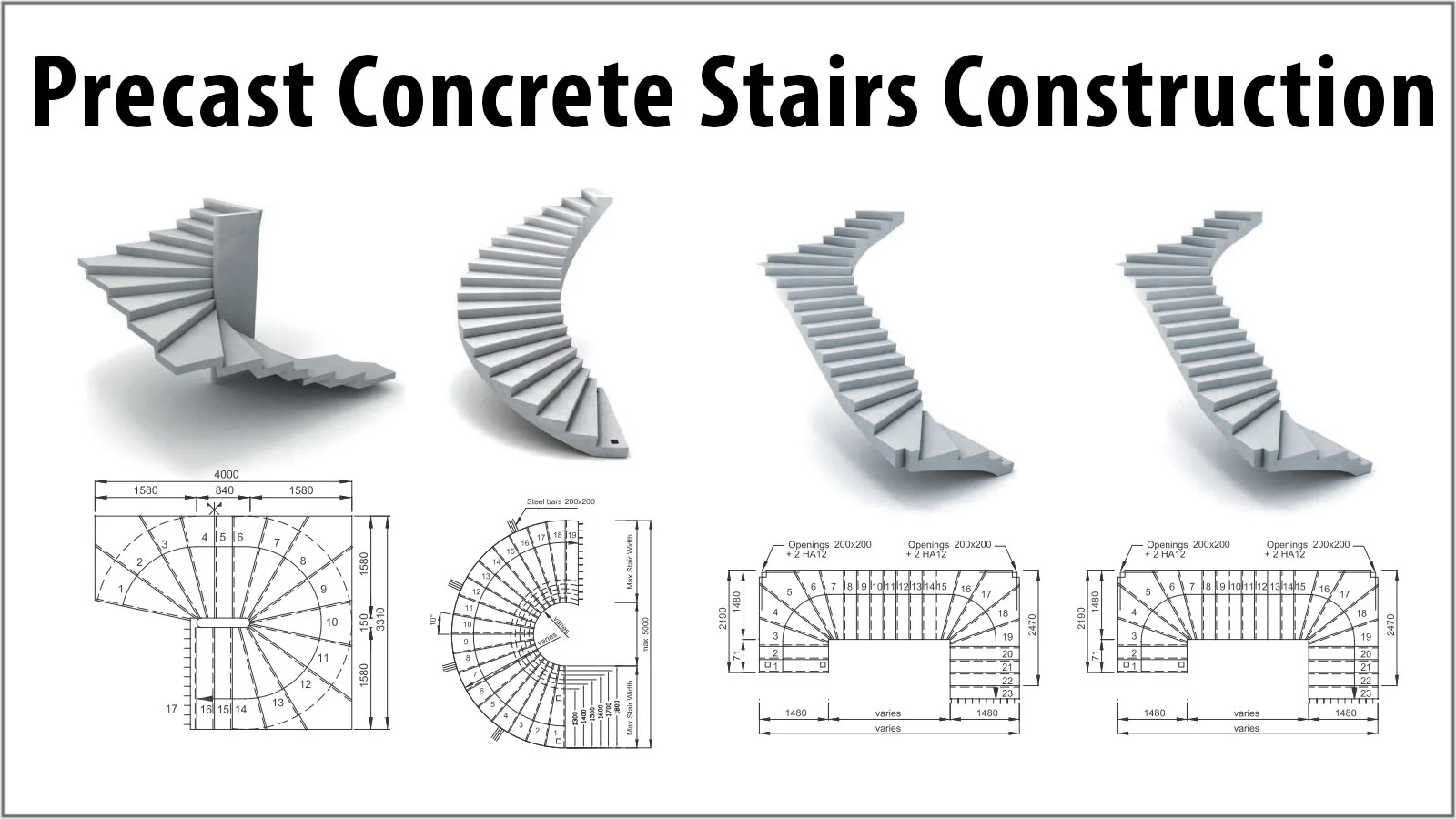

Quality control inspection producer Quality control inspection by the producer is a series of formalized activities and procedures. They are part of the fabricating or manufacturing operation of a producer of concrete materials, reinforcement producer/fabricators, or products, that furnishes to the construction industry rather than only to a specific project. Examples are operations of cement and aggregate producers, ready-mixed concrete producers, precasters, prestressing concrete fabricators, and reinforcing steel mills and fabricators. Production inspection personnel operate essentially the same way as those described for the contractor.They aid in ensuring that finished products will meet general specifications or those specifications relative to a specific project.

Regulatory inspection A series of formalized activities and procedures used by governmental bodies (such as licensing boards and building permit boards), charged with responsibility for enforcing building codes and other regulations. In this case, the inspectors have the responsibility for ensuring that the finished structure conforms to the requirements of the codes or regulations. The organization and activities of these inspectors are governed almost entirely by legal regulations.

Collection of Design Excel Sheets Click Here

Inspection team

Regardless of classification, an inspection team or group may consist of a number of individuals or, for very small projects, a single individual. Inspection, including testing,may be performed by a variety of groups such as:

Owner’s inspection personnel—Qualified inspection personnel maintained by the owner. Examples would be permanent or semipermanent personnel of governmental agencies, or large industries with continuing building programs.

Architect/engineer’s inspection personnel—Inspectors trained, certified, and maintained by a firm for work on projects designed by the firm.

Laboratory’s inspection force inspection personnel trained, certified, and maintained by a testing laboratory to provide contractual testing and inspection services.

Contractor’s inspection force Inspection personnel trained, certified, and maintained by a contractor to provide quality-control (in-process) inspection on projects it constructs.

Material manufacturers and suppliers inspection force Inspection (and testing) force trained, certified, and maintained by a concrete material and product manufacturing and fabricating firm for its own in-house use in quality-control (in-process) inspection and testing.